Pressure Vessel and Autogas Tank Production Line

Pressure Vessel and Autogas Tank Production Line, mainly focused on the LPG road tank production, Oil Tank Production, LPG Storage Tank Production, which has now become the growing business in Southern-East Asia, South America and Africa. Compared with import these huge tanks from China or else where, manufacturing locally will save a lot cost on the international shipment and customs tax fee. THLPG undertakes project design, manufacture and installation of turnkey plants for all types and sizes of LPG road tank, Automotive Gas Tanks, Oil Tank, LPG Storage Tank, Diesel Tank, Gasoline Tank etc. Especially in compliance with all relevant international standards such as EN, DOT, BS, KS etc. No need huge investments, we can help you fulfill your business dream and start production!

Production Line Specification

The Reasons to Choose THLPG:

We are a manufacturer of all LPG cylinder / Propane cylinder / LPG Tank making machinery with more than 26 years of experience, such as End Shell Production Line, Cover Production Line, Polishing trimming & joggling machines, inside and outside seam welding machines, inside and outside flange welding machines, basement welding machines, hydrostatic testing machine, air leakage testing machine, wet painting machine, blasting machine, rolling machine, metal sheet cutting machine and other LPG gas cylinder making machine, other gas cylinder welding line and other LPG Production Line Machinery. With advanced technology and best service, we have cooperated with many clients from all over the markets like Philippines, Malaysia, Bangladesh, Vietnam, Turkey, Colombia, India, Venezuela etc.

Main Products

Pressure vessel has a wide range. THLPG focuses on the big pressure vessel with energy usage, such as LPG road tank, LPG storage tank, Diesel tank, LNG tank etc.

LPG Semi Trailer

LPG Bobtail Tanker

Cryogenic Liquid Cylinders

Pressure Vessel

LNG Storage Tank

Introduction: Production Plant and Technology for LPG Storage Tank

The production quality of LPG storage tanks is related to the safety of energy storage. I will start with the inspection of raw materials and introduce the core processes such as molding, welding, and inspection in turn to demonstrate its rigorous production process.

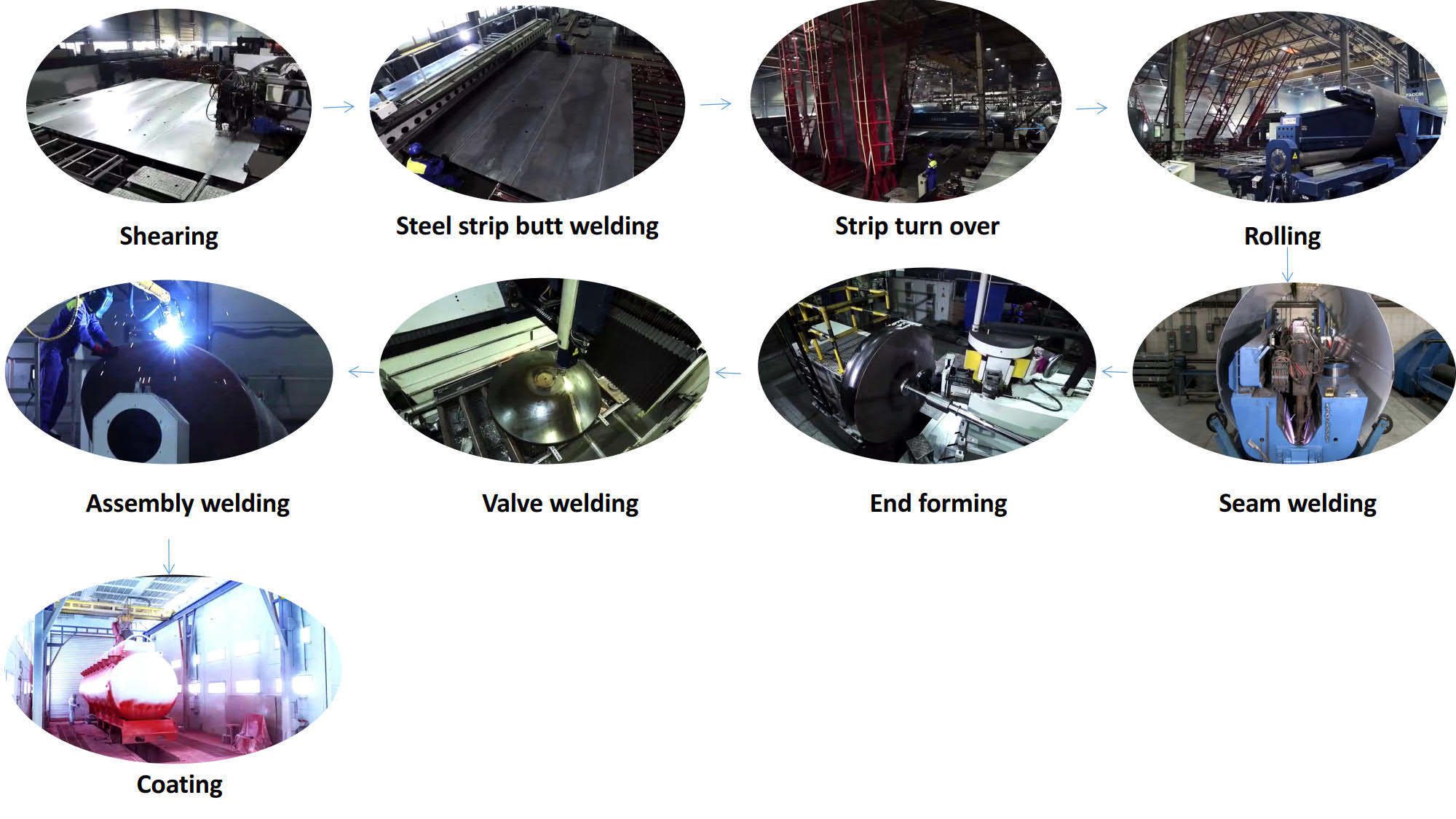

Major Process Flow

As the core equipment for storing high-risk media, the scientific and rigorous production process of LPG (liquefied petroleum gas) tanks is crucial. The production of LPG tanks starts with the inspection of raw materials. High-strength, corrosion-resistant high-quality steel is selected, and the thickness, chemical composition, mechanical properties, etc. of the plate are strictly tested to ensure compliance with national standards.

After the material inspection is qualified, it enters the forming process. The steel plate is rolled into the cylindrical shape required for the tank body by a plate rolling machine, and the head is made by stamping equipment. Each forming process strictly controls the dimensional accuracy and surface quality. Welding is a key link in the production of storage tanks. Automatic submerged arc welding, gas shielded welding and other processes are used to weld the longitudinal seams, circumferential seams and pipe welds of the tank body to ensure the strength and sealing of the welded joints. In order to ensure the quality of welding, it is necessary to strictly control the qualifications of welders and welding parameters, and use multi-layer and multi-pass welding technology to reduce welding deformation and defects.

After welding is completed, a comprehensive quality inspection should be carried out. Through non-destructive testing technology, such as ultrasonic testing and radiographic testing, internal defects of welds are detected; water pressure test and air tightness test are used to test the pressure bearing capacity and sealing performance of storage tanks. After passing the inspection, the surface of the storage tank is treated, and the surface roughness is improved by sandblasting and rust removal, and then anti-corrosion coating is applied to enhance the corrosion resistance of the storage tank and extend its service life.

The above are the main processes of LPG storage tank production. If you want to learn more about the details of a certain link, or have other related needs, please feel free to contact us.

Our Certification

FAQ

Headquartered in CHANGZHOU, China, THLPG has served the domestic market (65.00%), Southeast Asia (15.00%), Eastern Europe (10.00%), and South Asia (10.00%) since 1995. Now THLPG has the full technology and manufacturing capability for LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Pre-production samples before mass production;

Final inspection before shipment (SGS, CE, UL, CSA, ISO certification available);

Accept inspection by third-party agencies or customers before shipment.

All types of LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Accepted delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDU, DDP, DAP, Express;

Accepted payment currencies: USD, PHP, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF;

Accepted payment types: T/T, L/C, MoneyGram, PayPal, Western Union;

For each project, we could provide the design service since the beginning to help build the most cost efficient and suitable plant for customers. And the service will continue after the plant is well built. Engineers will stay for a period of time after the production line is installed to ensure that the production line runs smoothly. And the training for customer’s engineers is free of charge.

Please Feel Free to Contact Us!