LPG Cylinder and Other Old Containers Reconditioning Plant

LPG cylinder reconditioning line, also named as Propane tank reconditioning line, LPG Gas Cylinder refurbishment Line, which has now become the growing business in Southern-East Asia, South America and Africa. THLPG undertakes project design, manufacture and installation of turnkey plants for reconditioning of all types and sizes of Steel LPG Cylinders, Automotive Gas Tanks, LPG Cylinder Valves, especially in compliance with all relevant international standards such as EN, DOT, BS, KS etc. No need huge investments, we can help you fulfill your business dream and start Reconditioning!

Reconditioning Line Specification

The Reasons to Choose THLPG:

We are a manufacturer of all LPG cylinder / Propane cylinder making machinery with more than 26 years of experience, such as Guard Ring Reconditioning Line, Foot Ring Reconditioning Line, automatic polishing trimming & joggling machines, inside and outside bung welding machines, inside and outside foot ring welding machines, inside and outside guard ring welding machines, automatic propane cylinder furnace, automatic hydraulic pressure testing machine, automatic LPG cylinder tare weighing machine, automatic air leakage testing machine, automatic LPG cylinder blanking machine, automatic LPG cylinder plastic foaming machine, automatic LPG gas cylinder screen printing machine etc and other LPG gas cylinder making machine, other gas cylinder welding line and other LPG Reconditioning Line Machinery. With advanced technology and best service, we have cooperated with many clients from all over the markets like Philippines, Malaysia, Bangladesh, Vietnam, Turkey, Colombia, India, Venezuela etc.

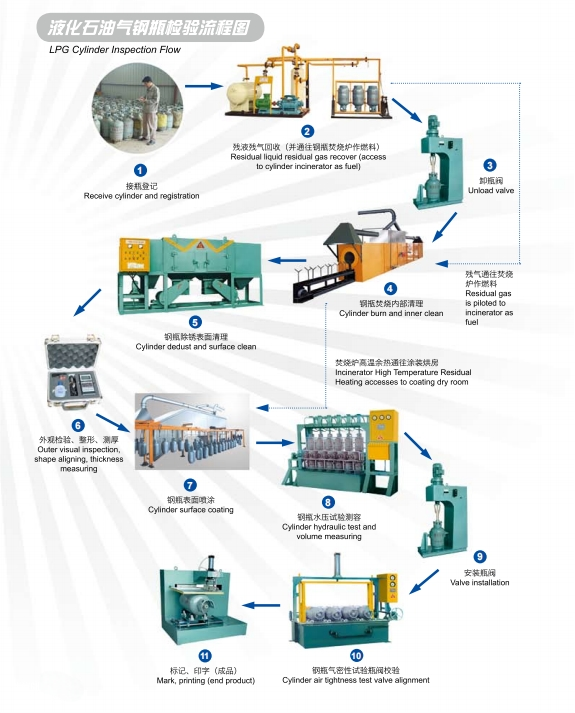

Process Flow

Old LPG Cylinder Recovery Line: Residual Recovery, Inner Cleaning, Valve Dismantling

There’s residual gas and liquid inside the old cylinders. It will cause explosion if it’s not vacuumed before valve taken off. So to assure the plant safety, the first step is to recover the residual gas and liquid inside the cylinder. And then the valves can be taken off. After the final cleaning of the gas and rust inside, the cylinders can be reconditioned.

Residual Liquid and Gas Recovery Machine

Cylinder Turn Over Rack

Valve Dismantling Machine

LPG Cylinder Reconditioning Line

The compatible Reconditioning line can refurbish various types and sizes of the used LPG cooking gas cylinders. The Reconditioning line is designed and produced by “THLPG”. It mainly consists Steam Cleaning Machine, LPG Cylinder Normalizing Furnace, Shot Blasting Machine, Hydrostatic Testing Machine, Air Leakage Testing Machine and other supplementary machines.

Unlike the brand new cylinder heat treatment, the reconditioning temperature only needs 500~600 degrees Celsius. Its main aim is to burn the old paints and rusts outside the cylinder. And to save time and steel grits on the shot blasting process.

Steam Cleaning Machine

Shot Blasting Machine

LPG Cylinder Normalizing Furnace

LPG Cylinder Hydrostatic Testing Line

After the heat treatment process, all cylinders are gradually cooled and then hydrostatically tested at 34 bar pressure to visually check for forming and welding defects. On request, we can provide a fully automatic in-line hydrostatic testing machine to reduce your workload and increase your Reconditioning efficiency.

Hydrostatic Testing Machine

Hydro Pressure Test Machine

Hydrostatic Test Machine for 45/50KG Cylinder

LPG Cylinder Recondition Finishing Line: Air Leakage Testing, Liquid Painting / Powder Coating, Silk Printing Machine

After hydro pressure testing process, LPG cylinders will be painted or coated. Then the cylinders will be installed with the new valves and do the air leakage testing. If all good, then the cylinders will be printed with the logo and go for packaging.

Powder Coating Line

Valve Mounting Machine

Air Leakage Test Machine

LPG Cylinder Finishing & Logo Printing Line

Net weight weighing, inline printing, valve thread cleaning, valve tightening, leak testing, vacuuming, laser marking, QR code installation and other processes are all automatically completed on the online finishing and leak testing line.

Single-color logos and labels are printed by screen printers, and multi-color logos are printed by automatic pad printers. Currently, many countries require QR codes to be attached to cylinders for subsequent safety management and traceability. China’s GB standard requires welding on the cylinder guard ring, and some countries allow rivets to be riveted on the guard ring.

Silk Printing Machine

Tare Weighing Line

Permanent Expansion Testing Machine

Our Certification

Customer Site Installation & Commission

Macao, China

Thailand

Philippines

Tunisia

Malaysia

Kenya

FAQ

Headquartered in CHANGZHOU, China, THLPG has served the domestic market (65.00%), Southeast Asia (15.00%), Eastern Europe (10.00%), and South Asia (10.00%) since 1995. Now THLPG has the full technology and manufacturing capability for LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Pre-production samples before mass production;

Final inspection before shipment (SGS, CE, UL, CSA, ISO certification available);

Accept inspection by third-party agencies or customers before shipment.

All types of LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Accepted delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDU, DDP, DAP, Express;

Accepted payment currencies: USD, PHP, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF;

Accepted payment types: T/T, L/C, MoneyGram, PayPal, Western Union;

For each project, we could provide the design service since the beginning to help build the most cost efficient and suitable plant for customers. And the service will continue after the plant is well built. Engineers will stay for a period of time after the production line is installed to ensure that the production line runs smoothly. And the training for customer’s engineers is free of charge.

Please Feel Free to Contact Us!