The construction of an automated production plant for liquefied gas cylinders requires consideration of safety, compliance, and automation efficiency. The following is a brief description of the entire process from the preparation stage to the commissioning and operation, with an emphasis on the special requirements of automated production:

I. Preliminary preparation stage

1. Market and feasibility research

Demand analysis: Investigate the market capacity, mainstream specifications (such as 5kg, 15kg, 50kg, etc.) and competitive landscape of liquefied gas cylinders in the region, and clarify the target production capacity (such as 1 million per year).

Technical feasibility: Evaluate the technical maturity of the automated production line, compare the cost-effectiveness of full automation and semi-automation (such as equipment investment, energy consumption, and labor costs), and refer to the production model of industry benchmark companies (such as the automation plan of large domestic cylinder companies).

Policy compliance: Confirm the local access requirements for dangerous goods manufacturers, such as the “Special Equipment Safety Law” on the licensing of gas cylinder production, and obtain a “gas cylinder manufacturing license”.

2. Site selection and planning

Site selection requirements:

Away from sensitive areas such as residential areas and schools (usually a safety distance of ≥500 meters is required), close to the steel raw material production area or logistics hub to reduce transportation costs.

The site needs to be flat, with good water supply and drainage, and power supply (automation equipment needs stable voltage, and it is recommended to be equipped with a backup generator).

Plant planning:

Divide functional areas: raw material storage area, production workshop (including head stretching, welding, testing and other processes), finished product storage area, office area, hazardous goods temporary storage area (such as paint, liquefied gas residual liquid).

Automation layout: Plan according to the assembly line direction of “raw material input → processing → testing → packaging” to reduce the material handling distance. For example, the head stretching equipment and welding equipment need to be arranged adjacent to each other for easy automatic transmission.

3. Approval and qualification processing

Core approval process:

Apply for a “Special Equipment Manufacturing License” from the local market supervision department, and submit the plant design drawings, equipment list, and quality control system documents.

Approval by the fire department: The factory building must comply with the “Code for Fire Protection Design of Buildings” (GB50016), and be equipped with explosion-proof walls, fire sprinkler systems, and emergency evacuation passages.

Environmental protection approval: Submit an environmental impact assessment report, treat production wastewater (such as oily wastewater) and waste gas (welding smoke, spraying volatiles), and be equipped with waste gas treatment devices (such as activated carbon adsorption).

Safety evaluation: Entrust a third-party agency to conduct a safety pre-evaluation to ensure that the production line complies with the “Implementation Measures for Safety Production Licenses for Dangerous Chemical Production Enterprises”.

4. Technology and equipment selection

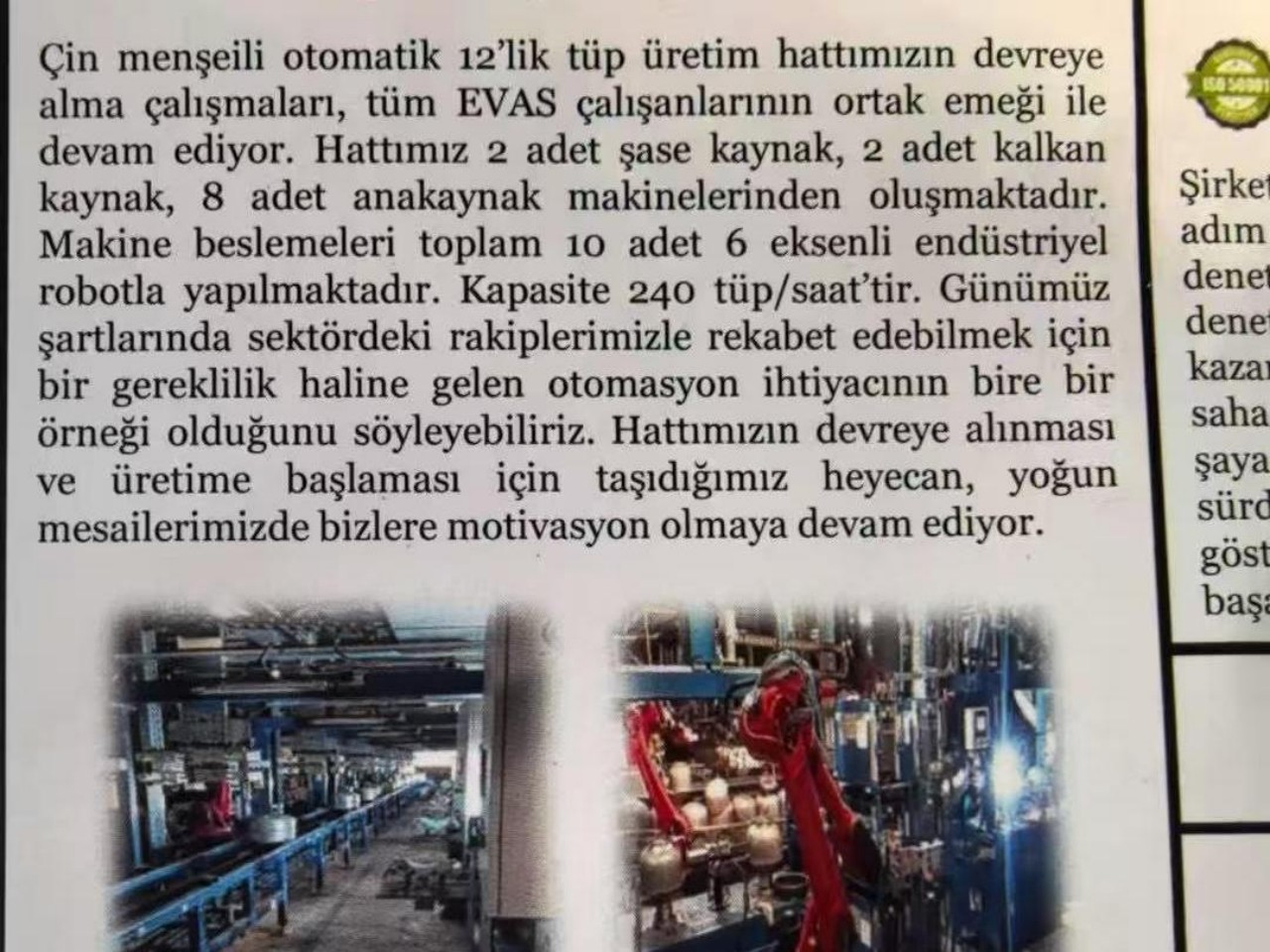

Core equipment for automated production lines:

Head processing: fully automatic laminating and stretching machine (refer to the laminating technology compared in the previous period), CNC hemming machine, and supporting automatic feeding robot arm.

Cylinder manufacturing: plate rolling machine, longitudinal seam automatic welding machine (such as submerged arc welding machine), circumferential seam welding robot (to achieve automated welding of head and cylinder).

Testing equipment: hydraulic pressure tester (pressure resistance test), air tightness detector (leak detection), X-ray flaw detector (weld detection), which need to be integrated into the automated assembly line.

Surface treatment: automatic spraying line (primer + topcoat), equipped with environmentally friendly paint recycling device.

Intelligent system:

Introduce MES (manufacturing execution system), monitor production data (such as production capacity, equipment failure, quality inspection results) in real time, and connect to ERP system to manage inventory and orders.

Use PLC (programmable logic controller) to control the linkage of production lines, such as automatic transmission to welding stations after the head stretching is completed.

II. Construction phase

1. Plant and infrastructure construction

Plant design standards:

The main structure adopts steel structure or reinforced concrete, the roof is equipped with explosion-proof pressure relief device (such as lightweight roof panel), and the ground is made of anti-static material (to avoid sparks caused by friction).

The span of the production workshop must meet the equipment layout. For example, the height of the stretching machine is usually 5-8 meters, and hoisting space must be reserved; the workshop ventilation must be good to prevent the accumulation of welding smoke.

Supporting facilities:

Build an independent power distribution room equipped with a lightning protection grounding system (grounding resistance ≤4Ω); set up a compressed air station to provide power for pneumatic equipment (such as robotic arms). Dangerous goods warehouses must comply with the “Hazardous Chemicals Warehouse Construction Standards”, use fireproof and explosion-proof walls, and install temperature and humidity monitoring and gas leakage alarm devices.

2. Installation and debugging of automated equipment

Installation process:

Locate the equipment foundation according to the process layout diagram, and cast the concrete base (such as the base of the stretching machine needs to be shockproof).

Lift the core equipment, use a level to calibrate the verticality (such as the horizontality error of the welding robot base ≤0.5mm/m), and connect the hydraulic and pneumatic pipelines.

Lay an industrial network (such as Ethernet), connect the PLCs of each device, and build a central control system.

Debugging focus:

Single machine debugging: Test the pressure parameters of the stretching machine and the trajectory accuracy of the welding robot (error ≤0.2mm).

Linkage debugging: Simulate the entire process from raw materials on the line to finished products off the line, detect the smoothness of the connection of the material transmission system (such as conveyor belts, truss manipulators), and ensure that the beat time meets the designed production capacity (such as the production cycle of each cylinder ≤10 minutes).

III. Preparation before production

1. Personnel training and system construction

Staffing:

Technical positions: Automation equipment engineer (responsible for PLC programming and equipment maintenance), quality inspector (certified and familiar with gas cylinder inspection standards).

Operation position: Production line operators who have undergone safety training must master emergency skills such as emergency shutdown and fire fighting.

Management system:

Establish ISO9001 quality management system, formulate production process regulations (such as welding parameters, stretching speed) and inspection standards for steel cylinders (refer to GB5842 “Liquefied Petroleum Gas Cylinders”).

Prepare “Safety Production Management System”, clarify the approval process for hot work and confined space work, and equip full-time safety officers.

2. Trial production and acceptance

Trial production:

Small batch production (such as 500 pieces), test the stability of the production line, record equipment failure rate and scrap rate (target ≤1%), and optimize process parameters (such as stretching die temperature and welding current).

Conduct full-item testing on the trial production cylinders: pressure test (water pressure ≥ 3.2MPa), air tightness test (air pressure ≥ 2.1MPa), paint film adhesion test.

Acceptance and evidence collection:

Invite the market supervision department to conduct on-site review, submit trial production records and test reports, and issue the “Special Equipment Manufacturing License” after passing.

Environmental protection acceptance: Entrust a third party to test the exhaust gas and wastewater emission indicators to ensure compliance with local emission standards.

IV. Key considerations

Safety redundancy design: The automated production line needs to be equipped with double safety protection (such as emergency stop button, overload protection), and key equipment (such as pressure vessels) needs to be calibrated regularly.

Cost control: The initial investment in automated equipment is high (about 60%-70% of the total investment), and it can be built in stages (such as the main production line first, and then improve the intelligent system later).

Compliance updates: Pay attention to industry standard updates (such as the revised version of GB5842), adjust the production process in a timely manner, and ensure that the product meets the latest safety requirements.

Through the above process, the construction of an automated production plant for liquefied gas cylinders can be systematically completed, taking into account efficiency, safety and compliance, and realizing large-scale and intelligent production.

E-mail: [email protected]

WhatsApp: +86 18811997342

Sales Engineer: Bruce Van

E-mail:[email protected]

WhatsApp: +86 18605247855

Sales Engineer: Herry Qin