Electric and Solar Water Heater Production Line

A water heater is a device that uses various physical principles to increase the temperature of cold water into hot water within a certain period of time. According to different principles, it can be divided into electric water heaters, gas water heaters, solar water heaters, magnetic water heaters, air water heaters, heating water heaters, etc.

The cold air manufacturing part and the hot water manufacturing part. In fact, these two parts are closely linked, inseparable, and must work at the same time. That is, while making hot water, the kitchen is cooled. Or in other words, while cooling the kitchen, hot water is also being made.

We mainly aim to help countries with high electricity and gas costs to build more economical water heaters. For example, storage electric water heaters and solar water heaters.

Electric water heaters are divided into three types: storage type, instant type (also known as fast type) and quick heating type. We focus on the manufacture of storage type enamel liner electric water heaters.

Storage type electric water heater (enamel liner water tank)

The water storage capacity is divided into 30L, 40L, 50L, 60L, 80L, 90L, 100L, etc.

Advantages:Easy to install, easy to use, not affected by the difference in natural gas floor pressure, the first choice of more and more users.

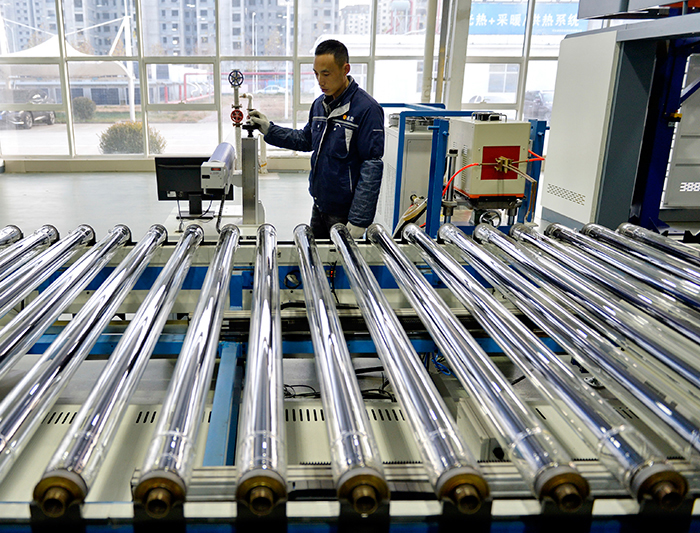

Solar water heater

Solar water heater is a water heater assembled with vacuum collector tubes. It can produce hot water as long as there is light, and can be widely used for household and industrial hot water. It is characterized by high heat collection efficiency (average daily efficiency ≥ 0.46), safety, cleanliness, energy saving, good thermal insulation performance, can be used all year round, and long service life. The specifications include 12 branches, 15 branches, 18 branches, 21 branches, 24 branches, etc. According to the installation method, it can be divided into roof-type solar water heaters and balcony-type solar water heaters; according to the pressure of the water tank, it can be divided into pressurized solar water heaters and non-pressurized solar water heaters.

Production Line Specification

The Reasons to Choose THLPG:

We are machine manufacturer of all Enamel Electric Water Heater and Solar Water Heater making machinery with more than 26 years of experience, such as water heater inner tank welding Line, solar water heater production line, solar water heater hole punching machines, solar water heater assembly machines, electric water heater enameling machines, electric water heater foam filling machines, automatic seam longitudinal welding machine, automatic seam circumferential welding machine, flange welding machine, pipe welding machine, tube welding machine and other gas cylinder welding line and other Welded Type Container Production Line Machinery. With advanced technology and best service, we have cooperated with many clients from all over the markets like Philippines, Brazil, Russia, Malaysia, Bangladesh, Vietnam, Turkey, Colombia, India, Venezuela etc.

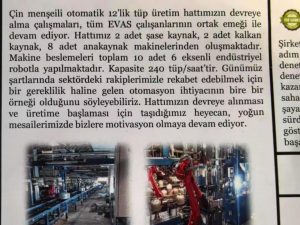

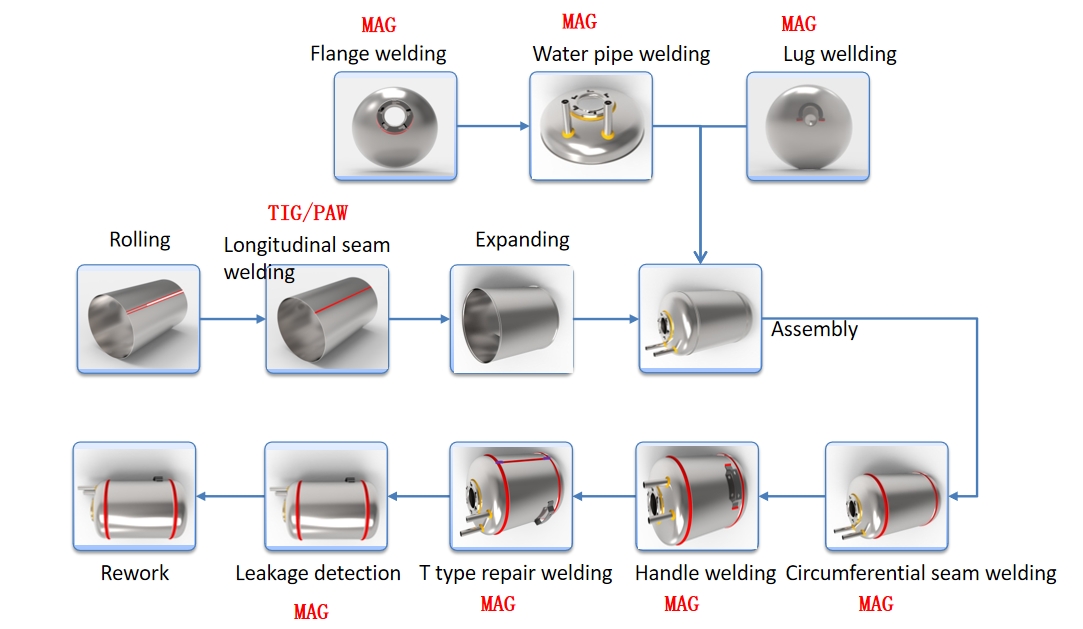

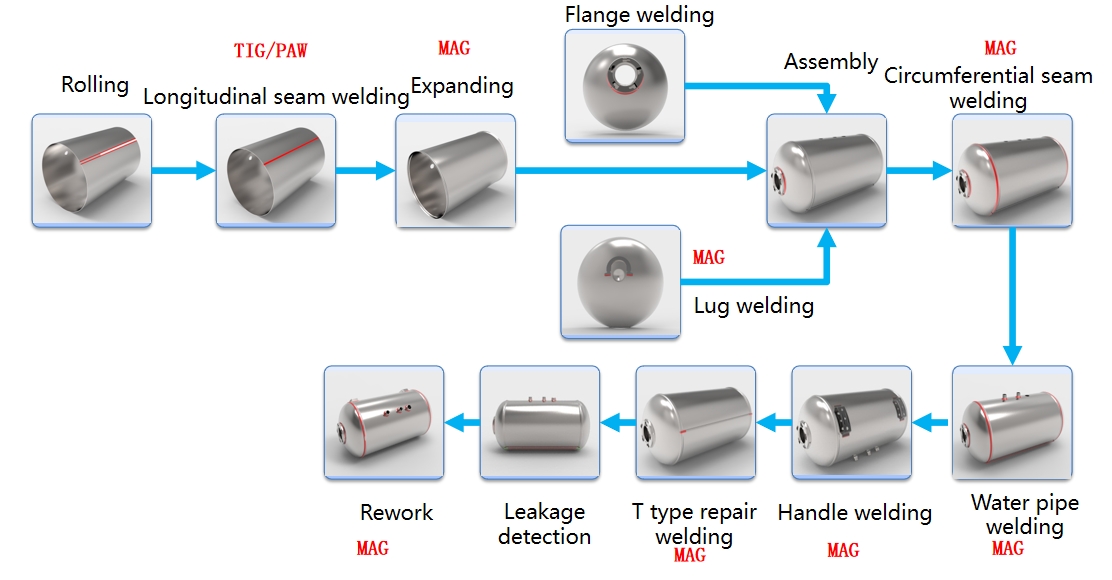

Production Flow:

Vertical type welding process( Type – A/AB)

Horizontal type welding process( Type – B)

Oval type welding process( Type – C)

Water Heater Body Blanking and Forming Line

The steel coils are cut to the required size by hydraulic blanking machines or mechanical punching machines. The steel coil blanks are manually/automatically loaded into a specific hydraulic deep drawing press to form the upper and lower halves of the water heater. The deep drawn parts are then expanded on the flange machine before welding so that the upper and lower parts match when assembled together.

Mechanical Press Blank Machine

Deep Drawing Hydraulic Press with Conveying Sets

Cylinder Halves Edge Flange Machine

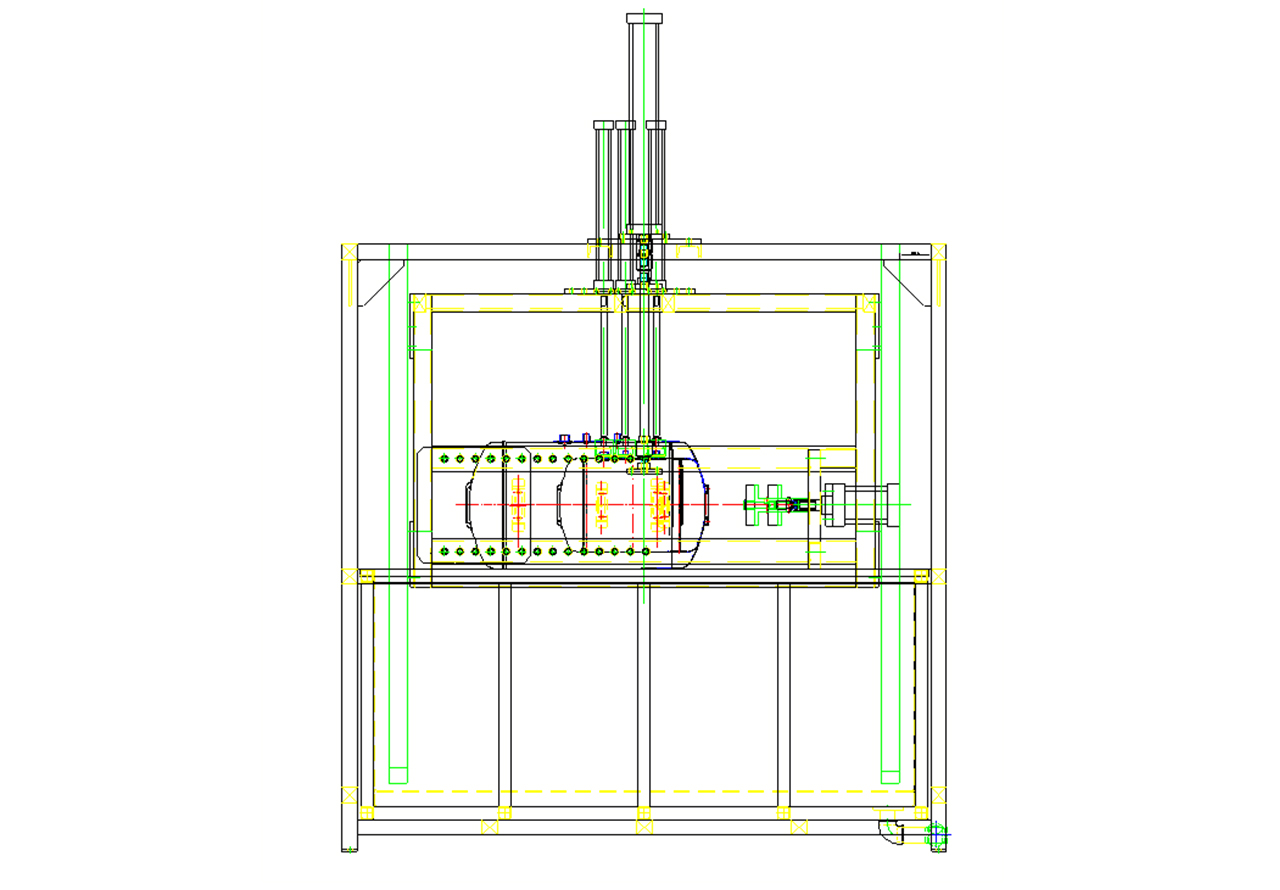

Electric Water Heater Inner Body Welding Line

Pipes and tubes are welded to the upper and lower half of the bottle body by an automatic welding machine. Flange is welded to the upper half of the bottle body. Then the upper and lower half of the bottle body will be welded together by an automatic circumferential seam welding machine. Three-piece water heaters are welded by special automatic longitudinal seam welding machine and circular seam welding machines. The most popular welding technology at present is MIG/MAG welding, which is economical and fast, thus greatly increasing production capacity. If local special gases are scarce, submerged arc welding technology can also be used.

Water Heater Tank Body Longitudinal Seam Welding Machine

Flange & Base Welding Machine

Water Heater Tank Body Circumferential Seam Welding Machine

Electric Water Heater Inner Tank Air Leakage Testing, Enameling and Foam Filling Line

Net weight weighing, inkjet printing, valve thread cleaning, valve tightening, leak testing, vacuuming, laser marking, QR code installation and other processes are all automatically completed on the online finishing and leak testing line.

Single-color logos and labels are printed by screen printers, and multi-color logos are printed by automatic pad printers. Currently, many countries require QR codes to be attached to cylinders for subsequent safety management and traceability. China’s GB standard requires welding on the cylinder guard ring, and some countries allow rivets to be riveted on the guard ring.

Air Leakage Testing Machine

Enameling Line

Tare Weighing and Vacuum Line

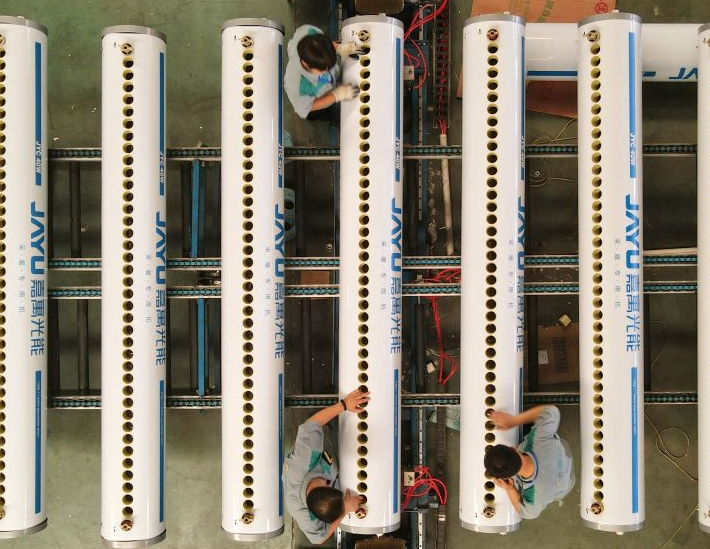

Solar Water Heater Production Plant

Solar Water Heater is simplified in production, no need many welding machinery. Its main body is formed by the rolling and edging machine. The holes for pipes are punched after rolling by the mechanical press. There are also the inner tank and outer shell on the solar water heater. The whole production line will be more focused on the crimping, resistant welding, conveying, assembly and packaging.

Solar Water Heater Inner Tank Production Line

Solar Water Heater Production Plant

Accessory Machining Center

Heat Rods for Solar Water Heater

Solar Water Heater Assembly

Polyurethane Foam Filling Machine

Our Certification

FAQ

Headquartered in CHANGZHOU, China, THLPG has served the domestic market (65.00%), Southeast Asia (15.00%), Eastern Europe (10.00%), and South Asia (10.00%) since 1995. Now THLPG has the full technology and manufacturing capability for LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Pre-production samples before mass production;

Final inspection before shipment (SGS, CE, UL, CSA, ISO certification available);

Accept inspection by third-party agencies or customers before shipment.

All types of LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Accepted delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDU, DDP, DAP, Express;

Accepted payment currencies: USD, PHP, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF;

Accepted payment types: T/T, L/C, MoneyGram, PayPal, Western Union;

For each project, we could provide the design service since the beginning to help build the most cost efficient and suitable plant for customers. And the service will continue after the plant is well built. Engineers will stay for a period of time after the production line is installed to ensure that the production line runs smoothly. And the training for customer’s engineers is free of charge.

Please feel free to Contact Us!