Beer Keg and Beverage Keg Production Line

The production of metal beer kegs is a process that perfectly combines industrial aesthetics with precision craftsmanship. Each process embodies the wisdom and concentration of craftsmen to ensure that the final product can provide an ideal storage and transportation environment for beer.

The Reasons to Choose THLPG:

We are a manufacturer of Beer Keg, Beverage Keg and other kegs making machinery with more than 26 years of experience, such as Beer Keg Production Line, Beverage Keg Production Line, automatic polishing trimming & joggling machines, inside and outside bung welding machines, inside and outside foot ring welding machines, inside and outside guard ring welding machines, automatic hydraulic pressure testing machine, automatic tare weighing machine, automatic air leakage testing machine, automatic blanking machine, automatic plastic foaming machine, automatic screen printing machine etc and other keg making machine, other keg seam welding line and other LPG Production Line Machinery. With advanced technology and best service, we have cooperated with many clients from all over the markets like Philippines, Malaysia, Bangladesh, Vietnam, Turkey, Colombia, India, Venezuela etc.

The first step in production is material selection. High-quality metal beer kegs usually use food-grade stainless steel or aluminum alloy as raw materials. Stainless steel has excellent corrosion resistance and strength, can effectively resist the erosion of acidic substances in beer, and will not react chemically with beer, ensuring the purity of beer flavor; aluminum alloy has unique advantages in easy handling and transportation due to its light weight, and also has good corrosion resistance. After selecting the material, the metal sheet is precisely cut according to the design specifications of the beer barrel. The cutting process uses high-precision laser cutting or CNC stamping equipment to ensure that the size error of each metal sheet is controlled within a very small range, laying the foundation for subsequent assembly.

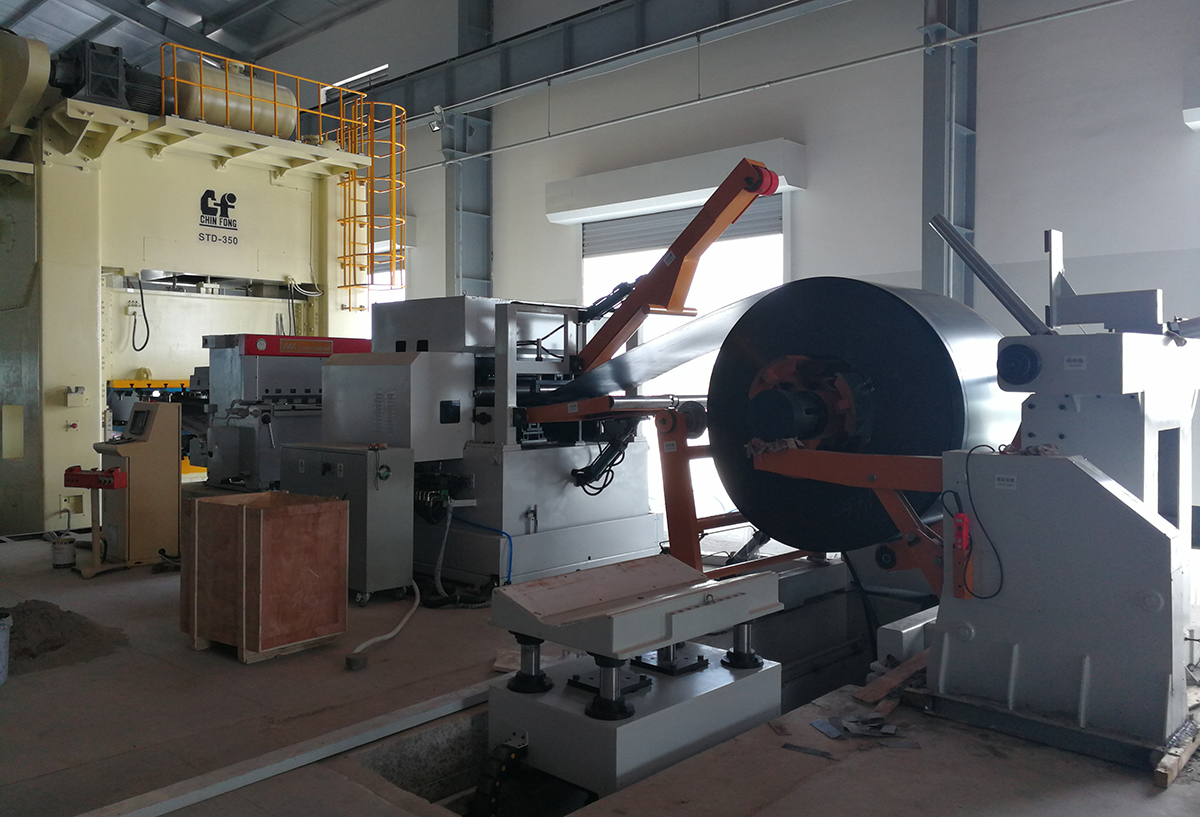

Straightening and Decoiling Machine

Stainless Steel Coil for Blanking

Metal Sheet before Deep Drawing

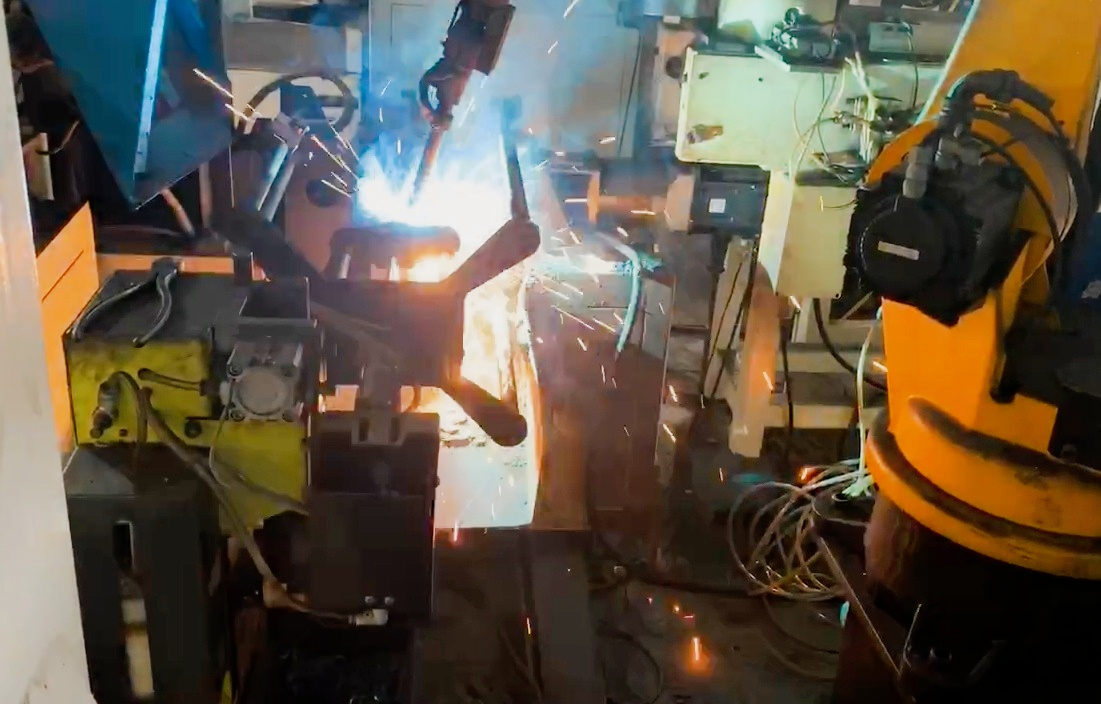

Then enter the barrel body forming stage. The cut metal sheet is sent to the plate rolling machine. Through the precise mechanical pressure, the flat sheet is rolled into the cylindrical shape of the barrel body. Subsequently, the longitudinal seams of the barrel body are welded using welding technology. In modern production, argon arc welding or laser welding processes are mostly used. These two welding methods can not only form a strong weld, but also ensure that the weld is flat and smooth, avoiding residual dirt and breeding bacteria during beer storage. After the barrel body is formed, it needs to be shaped. Through special molds and pressure equipment, the roundness and size of the barrel body meet the standard requirements to ensure the sealing and stability of the beer barrel in subsequent use.

Deep Drawing Hydraulic Presser

Hole Punching Mechanical Presser

Keg Edge Trimming and Polishing Line

The production of the barrel bottom and barrel cover is also critical. They are generally stamped from a whole piece of metal sheet. The design accuracy of the stamping die directly affects the quality of the barrel bottom and barrel cover. After the stamping is completed, the edge of the barrel bottom and barrel cover should be processed to make the edges smooth and have a suitable curvature so that they fit perfectly with the barrel body. The connection between the barrel bottom and barrel cover and the barrel body adopts welding technology. In order to ensure the sealing effect, sealing strips will be added at the joints during welding to form a double sealing guarantee.

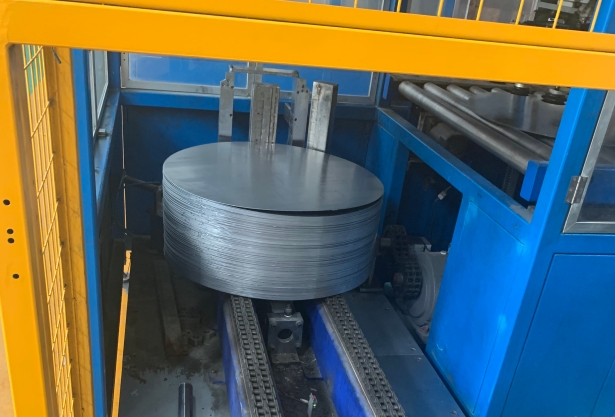

Keg Bottom and Cover Ring Forming

Keg Bottom and Cover Ring

Keg Bottom

The installation of valves and accessories of beer barrels is an important part of giving them functionality. According to the use requirements of the beer keg, different types of valves are installed, such as carbon dioxide intake valves, beer drain valves, etc. There are strict requirements for the installation position and method of these valves. During the installation process, multiple debugging is required to ensure that the valves are flexible and well sealed. At the same time, accessories such as pressure gauges and safety valves will be installed to ensure the safety of beer kegs during storage and transportation.

Keg Circumferential Seam Welding Machine

Keg Bung (valve seat) Welding Machine

Keg Inspection and Packing

After completing the above steps, the beer keg enters the quality inspection stage. First, a sealing test is carried out. The beer keg is filled with gas at a certain pressure, and then immersed in water to observe whether there are bubbles to determine whether the sealing performance of the beer keg meets the standard. Then a pressure test is carried out to gradually increase the pressure in the beer keg to test the maximum pressure value it can withstand, to ensure that the beer keg will not break or leak during normal use and transportation. In addition, the appearance of the beer keg will be inspected to see if there are defects such as scratches and dents on the surface, and whether the welds are uniform and flat.

Finally, the beer kegs that have passed strict inspections will be cleaned and surface treated. Use a special cleaning agent to thoroughly clean the inside of the beer barrel to remove impurities and oil residues left over from the production process, then rinse it with high-pressure water and dry it. In order to improve the aesthetics and corrosion resistance of the beer barrel, its surface will be polished, painted or electroplated to give it a smooth and bright appearance while enhancing its wear and corrosion resistance.

Valve Testing Machine

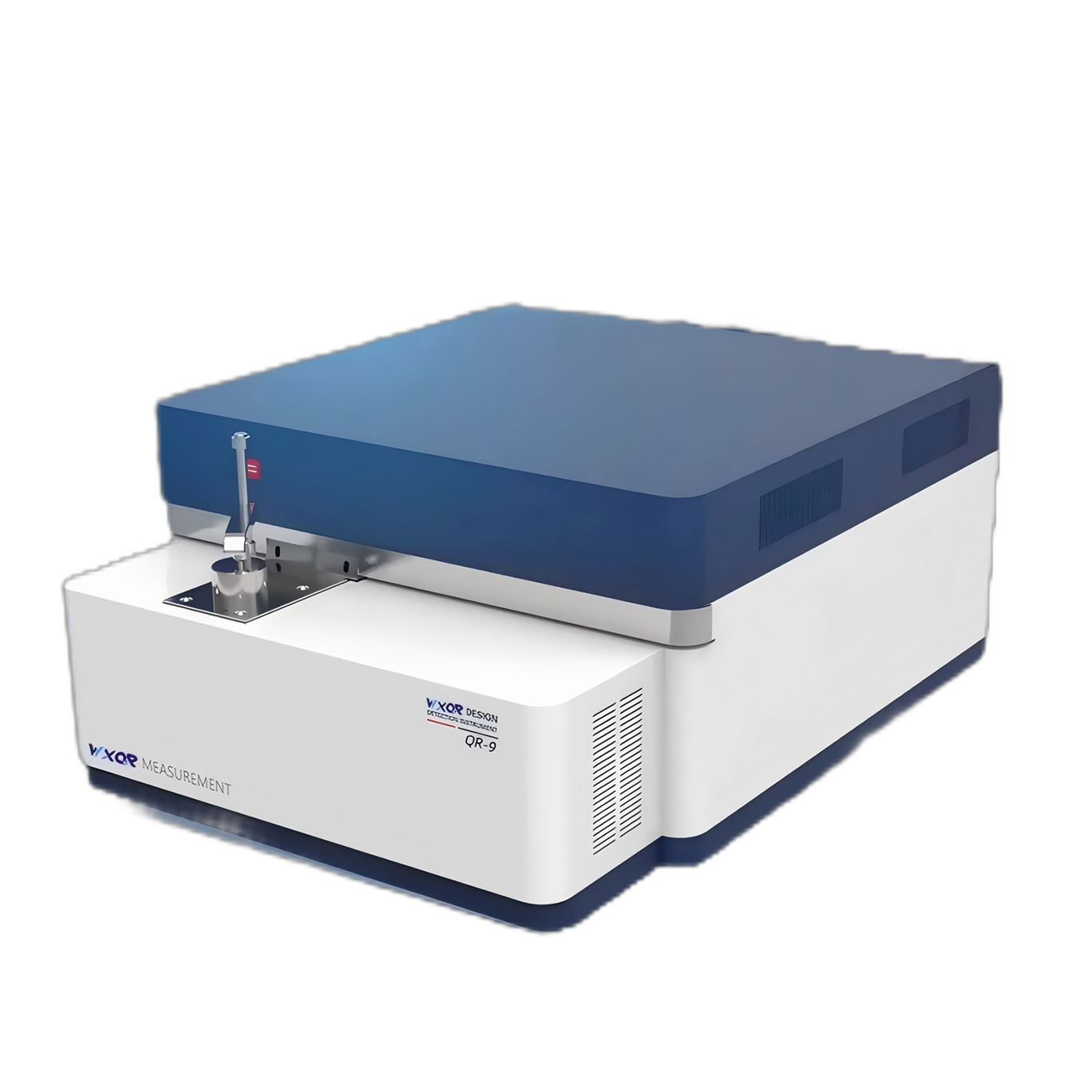

Spectrometer

Tensile and Bending Testing Machine

Inline X-Ray Testing Booth

Burst Test and Aging Test Machine

Permanent Expansion Testing Machine

Our Certification

FAQ

Headquartered in CHANGZHOU, China, THLPG has served the domestic market (65.00%), Southeast Asia (15.00%), Eastern Europe (10.00%), and South Asia (10.00%) since 1995. Now THLPG has the full technology and manufacturing capability for LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Pre-production samples before mass production;

Final inspection before shipment (SGS, CE, UL, CSA, ISO certification available);

Accept inspection by third-party agencies or customers before shipment.

All types of LPG Cylinder and Propane Tank Production Line, Electric and Solar Water Heater Production Line, Pressure Vessel and Auto-gas Tank Production Line, Beer Keg and Beverage Keg Production Line, LPG Cylinder and Other Old Containers Reconditioning Plant and other container testing and refurbishment machinery.

Accepted delivery terms: FOB, CFR, CIF, EXW, CIP, FCA, DDU, DDP, DAP, Express;

Accepted payment currencies: USD, PHP, EUR, JPY, CAD, AUD, HKD, GBP, RMB, CHF;

Accepted payment types: T/T, L/C, MoneyGram, PayPal, Western Union;

For each project, we could provide the design service since the beginning to help build the most cost efficient and suitable plant for customers. And the service will continue after the plant is well built. Engineers will stay for a period of time after the production line is installed to ensure that the production line runs smoothly. And the training for customer’s engineers is free of charge.

Please Feel Free to Contact Us!