Fully Automatic Welded Acetylene Cylinder Production Line

Production Process Design

| Process links | Automation equipment and technology | Remarks |

| Steel plate cutting | CNC fiber laser cutting machine | Cutting speed 1-3m/min, cut roughness Ra≤12.5μm |

| Rolling forming | Servo motor driven four-roll plate rolling machine | Automatic adjustment of rolling pressure, roundness error ≤1mm |

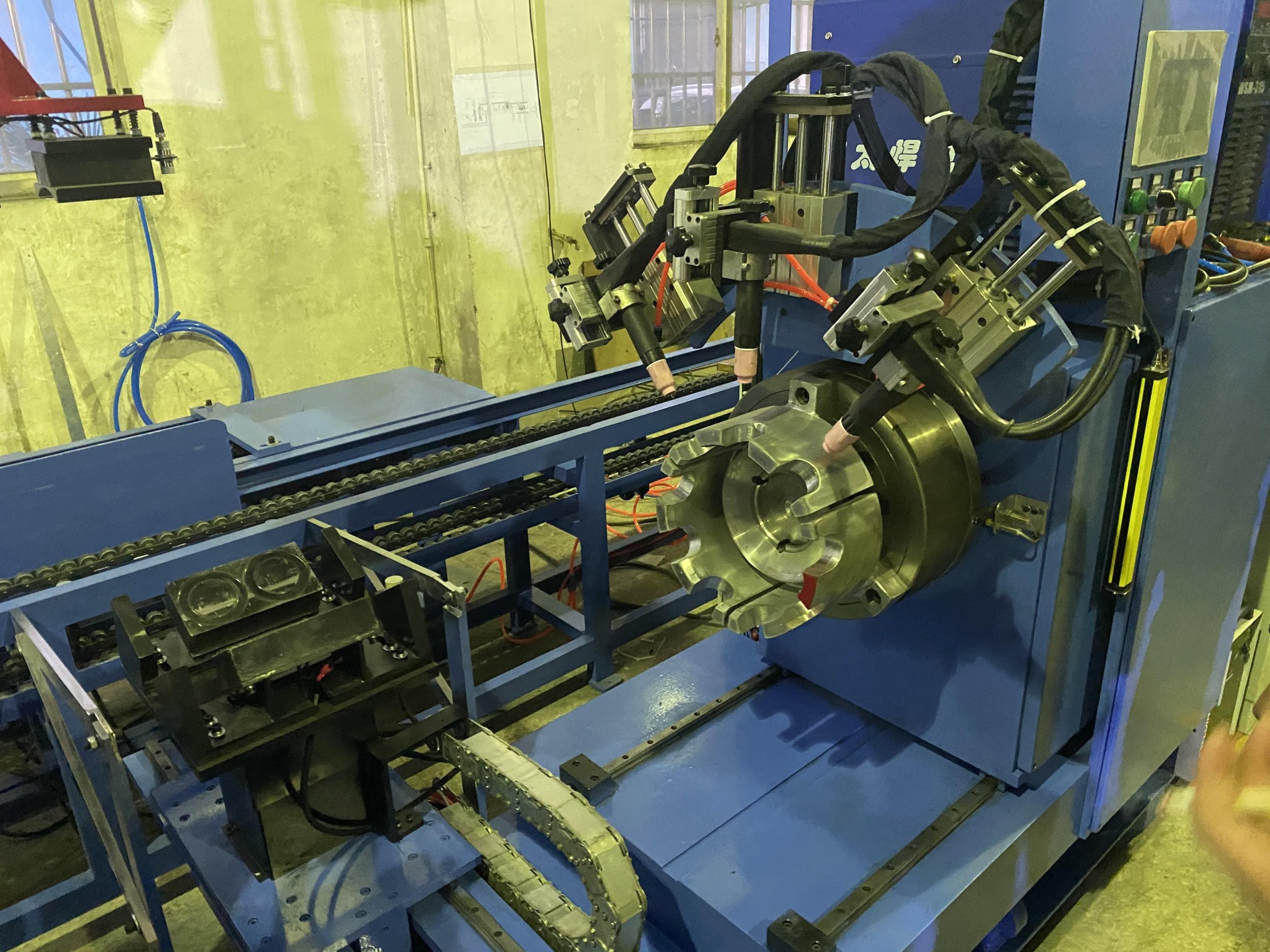

| Welding process | Fully automatic welding line + visual tracking system | Welding speed 6-10mm/s, weld pass rate ≥98% |

| Heat treatment | Intelligent temperature control box furnace + atmosphere protection system | Temperature control accuracy ±5℃, oxygen content in furnace atmosphere <1% |

| Surface treatment | Suspended automatic spraying line + drying tunnel furnace | Spraying efficiency 20-30 bottles/min, coating curing temperature 80℃ |

Technical advantages and industry applications

1. Production efficiency: The automated production line can produce 10-15 bottles per minute, and the annual production capacity of a single line can reach 500,000-800,000 pieces, which is 5-8 times more efficient than manual production lines.

2. Quality stability: Automated control of key processes increases the product qualification rate from 90% of manual production to 99.2%, and the pressure test leakage rate is ≤0.3%.

3. Safety compliance: The production line is equipped with explosion-proof electrical equipment and flammable gas alarm system, which complies with the requirements of GB 10879 “Safety Supervision Regulations for Dissolved Acetylene Cylinders” to ensure the inherent safety of the production process.

This type of production line is widely used in leading gas cylinder manufacturing companies (such as Tianhai Industry and CIMC Enric), and has passed international certifications such as EU TPED and US DOT to meet the safety standards of the global market.

1. Raw material pretreatment and bottle body forming

Material selection: HP295, HP345 and other special pressure vessel steels are used. Chemical composition analysis (such as carbon, manganese, sulfur, and phosphorus content control) and mechanical property tests (tensile strength, yield strength, etc.) are required to ensure that the steel meets the GB 5100 “Steel Welded Gas Cylinder” standard.

CNC blanking and rolling: The steel plate is cut into trapezoidal or rectangular blanks using a CNC laser cutting machine with an error control of ±0.5mm; cold rolling is performed using a four-roller plate rolling machine, and the curvature radius is monitored in real time during the rolling process to ensure that the bottle body roundness error is ≤1.5mm.

Intelligent welding: Robot argon arc welding or submerged arc welding technology is used to weld the longitudinal seams and circumferential seams of the bottle body. For example, during longitudinal seam welding, the robot automatically tracks the weld through a visual sensor, and the welding current and voltage parameters are adjusted in real time by the PLC system. After welding, the weld must pass 100% of the X-ray flaw detection (RT), and the defect level must not be lower than Level II in GB/T 3323.

2. Heat treatment and mechanical property optimization

Overall annealing treatment: Place the bottle body in a box-type resistance furnace and heat it to 650±20℃ at a heating rate of 50℃/h. After keeping warm for 2 hours, cool it to below 300℃ with the furnace. This process can eliminate welding stress, so that the tensile strength of the bottle body reaches 400-500MPa, and the elongation after fracture is ≥20%.

Bottle mouth strengthening treatment: The bottle mouth is cut by a CNC lathe to form a thread and a sealing cone. The thread accuracy must reach 6H/6g level; some high-end products will use a local quenching process for the bottle mouth to improve the wear resistance of the thread, and the hardness is controlled at HRC 28-32.

3. Surface treatment and installation of safety accessories

Anti-corrosion coating process: The bottle body is first sandblasted and derusted (Sa2.5 level) using an automatic spraying line, and then sprayed with epoxy zinc-rich primer (dry film thickness ≥ 80μm) and acrylic topcoat (dry film thickness ≥ 120μm). The coating adhesion reaches level 0 through the cross-cut test (ISO 2409).

Assembly of safety accessories: The bottle valve is made of copper alloy (such as HPb59-1) and is tightened with a torque wrench at a torque of 30-40N・m; the fusible plug must be tested for melting point before installation (melting at 70±5℃) and pass the air tightness test (no leakage under 0.6MPa air pressure).

E-mail: [email protected]

WhatsApp: +86 18811997342

Sales Engineer: Bruce Van